In 2007, before the large-scale use of nickel pig iron in China, electrolytic nickel plates were used in the global stainless steel industry. At that time, nickel was absolutely precious metal, with a price of more than 50,000 US dollars. When Chinese enterprises make use of low-grade laterite nickel ore to produce nickel pig iron (Nickel Pig Iron/NPI) on a large scale, the global nickel price hit the bottom once. A low nickel price has a far-reaching impact on the global stainless steel industry. Almost all cost lines have been broken, and more than half of the global electrolytic nickel plants can not make profits.

Nickel pig iron (NPI) is a real game changer

The large-scale use of domestic nickel pig iron has laid the cost advantage of Chinese stainless steel, which has changed the supply and demand pattern of Chinese stainless steel from the net import state before 2010 to the net export state. Trucks load raw nickel ore near Sorowako, Sulawesi, Indonesia

Trucks load raw nickel ore near Sorowako, Sulawesi, Indonesia

Indonesia, known as the "country of thousands of islands", has a complete variety of mineral resources and abundant reserves. Prior to the implementation of the original ore export restriction order in 2014, Indonesia ranked first in the world in laterite nickel ore exports, accounting for one fifth of the global total supply. In the past, enterprises that brought Indonesian and Philippine nickel mines to China for production are now more likely to build ferronickel factories directly in Indonesia. Following the implementation of the export ban on nickel ores, enterprises from Qingshan Iron and Steel, Delong Nickel Industry, Xinxing Pipe Casting, Dongfang Special Steel and Jinchuan Group have intensified their efforts to establish nickel smelters in Indonesia to meet the growing demand for nickel pig iron in China's stainless steel industry. With the continuous expansion of Indonesia's production capacity, it has replaced China as the largest producer of ferronickel. Investment from Chinese stainless steel enterprises is also extending to the middle and lower reaches of the industrial chain. Castle Peak Indonesia Production Base Nickel and Iron Production Line

Castle Peak Indonesia Production Base Nickel and Iron Production Line

"Four-in-one" stainless steel smelting, which changes the game rules of the world stainless steel industry. The technological revolution in China's stainless steel industry has led to a new industrial integration, which has resulted in RKEF ferronickel smelting technology and integrated steelmaking process bringing the global manufacturing cost of stainless steel to a new low.

Taking Castle Peak Indonesia project as an example, it has built the world's first "four-in-one" stainless steel smelting enterprise. With Qingshan Indonesia project's integrated red feeding process officially put into operation, its effect is to subvert the traditional steelmaking process. This indicates that the technological innovation of stainless steel industry is not only extending from raw materials to steelmaking, but also combining raw materials with steelmaking.

Castle Peak Indonesia Production Base Stainless Steel Hot Rolling Production Line

Electricity: the exclusive coal-fired power generated by low-cost self-owned power plants

Nickel: local laterite nickel ore + rotary kiln electric furnace = liquid nickel pig iron

Chromium: chromium ore + submerged arc furnace = Liquid ferrochromium

Iron: NPI (85%) and FeCr (40%) contain "free iron"

Qingshan Iron and Steel Indonesia has its own power generation, nickel production (using local laterite nickel ore), ferrochrome production (using South Africa's low-grade UG2 chrome ore), iron supply (from nickel pig iron, ferrochrome) in one, realizing the whole process industries of ferronickel red delivery, ferrochrome red delivery, stainless steel continuous casting, hot continuous rolling, cold rolling, etc. The cost of its stainless steel slab and hot rolled stainless steel sheet is at the lowest level in the world and is decoupled from the London Metal Exchange (LME) price.

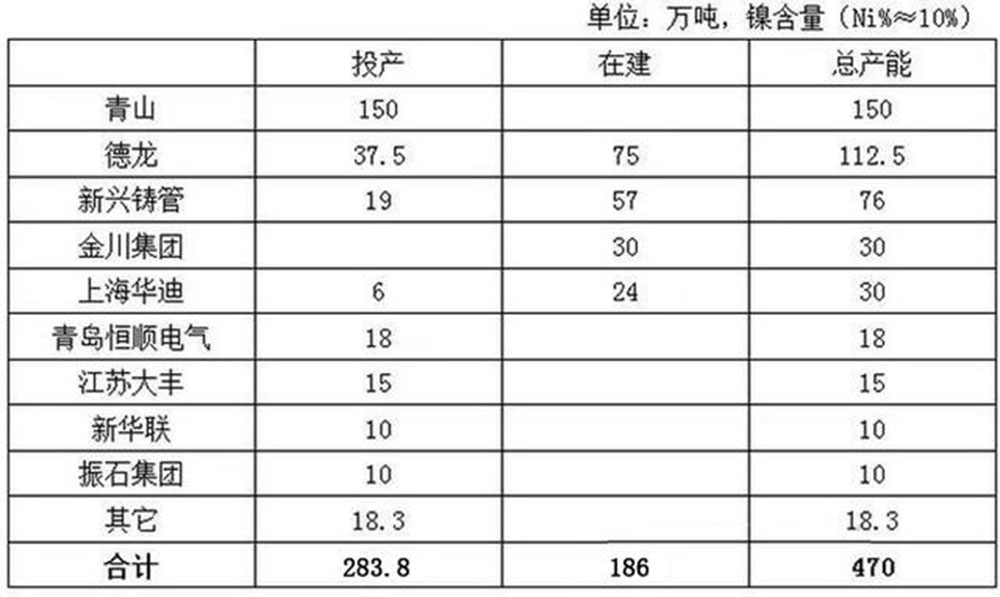

Projects Progress of Nickel Smelting Enterprises in China

Projects Progress of Nickel Smelting Enterprises in China

With the continuous expansion of new steelmaking plants and processing capacity of stainless steel follow-up products, it means that large investment from China is expected to make Indonesia/Philippines produce more stainless steel crude steel than Europe in 10 years.

In 2018, with the commissioning of Delong Nickel Indonesian Stainless Steel Plant and the further improvement of Qingshan Indonesia's stainless steel production, Indonesia's stainless steel production will reach 1 million tons.

In 2019, the new Indonesian stainless steel plant for cast pipes and the Philippine stainless steel plant will be put into operation. The output of Indonesian/Philippine stainless steel will reach more than 2 million tons.

In 2020, the output of Qingshan Indonesian Stainless Steel Plant will reach 2 million tons and Delong will further increase. The output of Indonesian/Philippine Stainless Steel will reach more than 3 million tons.

In 2021, Andere Indonesian Stainless Steel Plant will be put into operation, together with several other major plants to increase production, Indonesian/Philippine stainless steel production will reach more than 4 million tons;

Distribution of Chinese Nickel Smelting Enterprise Projects in Indonesia

Distribution of Chinese Nickel Smelting Enterprise Projects in Indonesia

In 2022, it will reach more than 5 million tons, 6 million tons in 2023, 7 million tons in 2024 and 7.4 million tons in 2025 (including 6.4 million tons in Indonesia and 1 million tons in the Philippines), thus exceeding the output of 7.3 million tons of stainless steel in Europe in 2016. Indonesian/Philippine production of stainless steel crude steel will rise and may exceed Europe in 10 years, which will have a significant impact on the global market.

Grasp nickel pig iron and Qingshan Iron and Steel with integrated technology to become the largest stainless steel producer in the world

In 2006, Qingshan Iron and Steel, located in Wenzhou, Zhejiang Province, produced less than 400,000 tons of stainless steel, with a revenue of only $953 million. By 2016, when the global output of stainless steel crude steel increased to 44.9 million tons, Qingshan Iron and Steel output reached 5.8 million tons. What does that mean? It took Qingshan Iron and Steel just 10 years to become the world's largest stainless steel manufacturer, holding fast to the integrated process of nickel pig iron and steelmaking. China's largest stainless steel industry base, Fujian Qingtuo Group Operational Management Center

China's largest stainless steel industry base, Fujian Qingtuo Group Operational Management Center

By 2020, Qingshan Iron and Steel's global total stainless steel production will reach 10 million tons, truly grasp the core "pricing dominance" of the future stainless steel slab industry, and become a global stainless steel industry game rule changer. In the future, it will become more difficult for steelmaking plants in western countries (steelmaking through stainless steel scrap) to create value. The production of stainless steel by RKEF process will be further increased, and some traditional steelmaking plants will be closed.

German ThyssenKrupp will sell Italian Telney Million Tons Stainless Steel Mill

German ThyssenKrupp will sell Italian Telney Million Tons Stainless Steel Mill

China's stainless steel industry started nearly 40 years later than the world's, but with the spirit of pioneering, innovative and divergent thinking of the Chinese people, China's stainless steel industry has achieved considerable development, and the status of the world's largest producer and output of stainless steel has been unshakable. Technology promotion is a major label for the development of stainless steel industry. The rapid growth of China's stainless steel industry is caused by the supply of raw materials, the improvement of production efficiency and the compression of production cost. Technological innovation has made great achievements in the past.

It is advisable to tread the waves when the tide rises, and sail when the wind blows. In the new year, China's stainless steel industry has shown a brilliant start; facing the future, China's stainless steel industry will achieve greater achievements.

Scan£¨Official Web 2-D Code